Ethane Recovery Project

Ethane Skid Design for 80 GPM Recovery

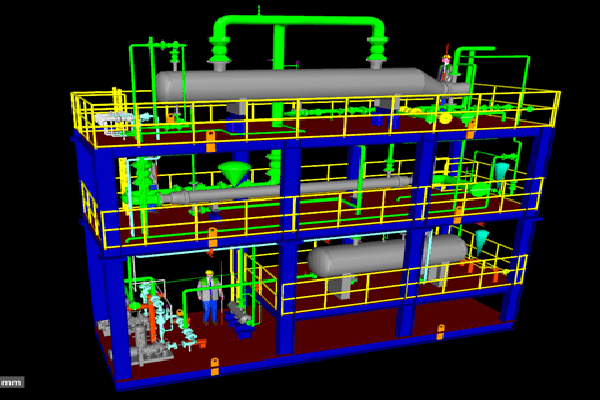

KED India was tasked with the detailed design of an ethane recovery skid capable of processing 80 GPM of ethane. The system included two heat exchangers and a propane refrigeration unit to chill and sub-cool the ethane product, supported by booster and pipeline pumps. The skid was designed in three sections to comply with the shipping height restriction of 13’6″.

Client Inputs :

- P&ID

- Plot Plan

- Mechanical and Instrument Data Sheets

- Piping Specifications

KED Scope of Work :

- 3D Modeling: Developed a 3D model in CADWorx 2012, incorporating heat exchangers, storage tanks, and pumps. The skid dimensions were 30 ft. (L) × 10 ft. (W) × 33 ft. (H), designed for shipment in three sections.

- Structural Analysis: Conducted structural analysis using ANSYS for lifting, transportation, and in-place scenarios. Provided a detailed BOM for structural steel and pipe supports.

- Piping Isometrics: Delivered isometric drawings with BOM and support details for approximately 40 skid lines.

- Equipment & Piping Layouts: Optimized layouts for efficient operation and maintenance.

- Skid Tie-in Coordinates: Supplied tie-in line coordinates for seamless field routing.

Significance of Ethane Recovery :

With the increasing global demand for ethylene, ethane recovery from natural gas is crucial. Modern techniques reduce operating costs and enhance efficiency by minimizing energy consumption. Our project addressed these challenges through innovative process optimization, enabling improved ethane extraction with higher purity and lower energy requirements.

Project Impact :

By leveraging advanced ethane recovery methods, the project optimized ethane production while maintaining cost-efficiency. Our expertise ensured compliance with global standards, making the project highly successful.