Piping Stress Analysis

Best Piping Stress Analysis Services by KED India

Our Piping Stress Analysis services ensure the reliability and safety of piping systems by

evaluating their response to various operational conditions, such as:

- Temperature changes – Expansion and contraction can cause stress.

- Pressure fluctuations – Variations may impact the structural integrity of pipes.

- External forces – Movement or vibration from nearby equipment can create stress points.

We use industry-standard tools such as Caesar II and Nozzle Pro to analyze and predict stress and loads on pipes, ensuring compliance with industry codes and standards.

Why Piping Stress Analysis is Essential

Piping systems play a critical role in industrial processes, and stress analysis helps prevent potential system failures by:

- Ensuring Safety – Protects the public by preventing catastrophic failures.

- Extending Equipment Life – Minimizes stress on equipment, reducing wear and preventing breakdowns.

- Compliance with Codes – Meets industry standards for safe design, fabrication, and operation.

When is Piping Stress Analysis Required?

Piping stress analysis is critical in situations such as:

- High-temperature pipelines (>250°F)

- Sensitive equipment connections

- Large diameter-to-thickness (D/t) ratios

- External pressure exposure

- Critical services with stringent safety requirements

Our Expertise in Piping Stress Analysis

We specialize in evaluating piping systems across various industries, with a focus on:

- Lines connected to pressure vessels – All lines 10″ and above.

- Lines connected to rotating equipment – All lines 3″ and above.

- Lines connected to air coolers/heat exchangers – All lines 4″ and above.

- Lines connected to flare headers – All lines 4″ and above.

Our Process

- Data Collection: Gathering all relevant details about the piping system.

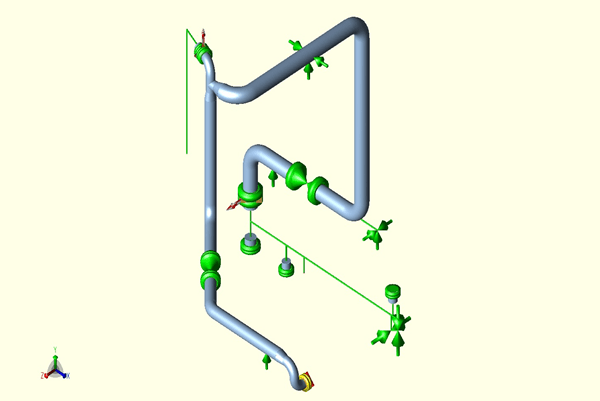

- Model Development: Creating accurate 3D models for analysis.

- Load Evaluation: Analyzing loads due to temperature, pressure, weight, and external

factors. - Compliance Check: Ensuring the system meets applicable industry standards.

- Recommendations: Providing practical solutions to optimize system performance.

Tools and Standards We Use

We utilize leading industry tools, including:

- Caesar II – For static and dynamic stress analysis.

- Nozzle Pro – To assess nozzle loads and pressure vessel connections.

We adhere to relevant international codes and standards, such as:

- ASME B31.1 (Power Piping)

- ASME B31.3 (Process Piping)

- API 610 (Centrifugal Pumps)

- API 650 (Storage Tanks)

Contact Us for Reliable Piping Stress Analysis

Our team is committed to providing cost-effective and accurate stress analysis solutions. We

work closely with clients to optimize existing pipe routing and ensure system safety and

performance.

Contact us today to learn more about how we can assist you with your piping stress analysis requirements.