Piping Stress Analysis

Piping stress analysis is a critical aspect of the design and maintenance of piping systems in various industries, including oil and gas, chemical processing, and power generation. The purpose of piping stress analysis is to ensure that piping systems are safe and reliable, and can withstand the forces to which they will be subjected during operation.

Piping Stress Analysis services are offered by a number of companies in Texas and Oklahoma, US and are essential for the safe and efficient operation of piping systems in these states. These services involve the use of specialized software and engineering techniques to analyze the stresses that will be imposed on a piping system during operation, and to identify any potential issues that may need to be addressed.

There are a number of benefits to using Piping Stress Analysis services in Texas and Oklahoma, US. These services can help to identify potential problems with a piping system before they occur, allowing for timely repairs or modifications to be made. This can help to prevent costly downtime and potential accidents or injuries. In addition, piping stress analysis can help to optimize the design of a piping system, reducing the overall cost of construction and operation.

Overall, Piping Stress Analysis services are an essential component of the design and maintenance of piping systems in Texas and Oklahoma, US. By ensuring that piping systems are safe and efficient, these services can help to protect both workers and the surrounding environment.

As a standard engineering practice, it is recommended that following lines to be evaluated for stress analysis:

♦ Lines connected to Pressure vessel: All lines 10″ and above.

♦ Lines connected to Rotating equipment: All lines 3″ and above.

♦ Lines connected to Air cooler / Heat Exchanger: All lines 4″ and above.

♦ Lines connected to flare header: All lines 4″ and above.

Contact us for additional information on this.

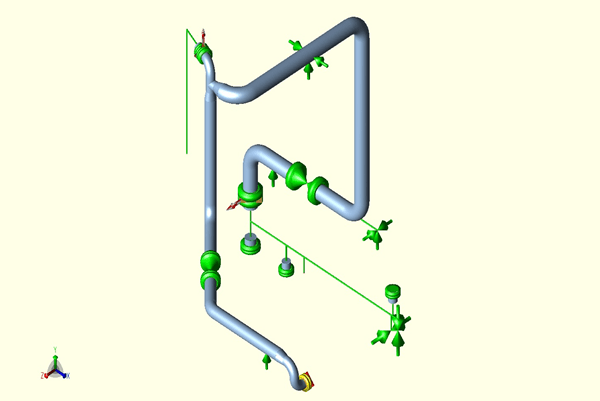

As a part of Piping stress analysis, we would provide simple solutions and would try to use your existing pipe routing as much as possible. We would use tools like Caesar, Nozzle Pro to analyze pipe / Nozzle for stress evaluation.

The Need for Piping Stress Analysis services in texas and oklahoma, US

Pipe Pressure analysis ought to be accomplished primarily to give security to the general public, whether you’re designing a building heating system or a high-pressure gas line at a refinery. Public security is paramount.

When a pipe collapse, is a just broken service the owner doesn’t connect the designer/engineer about it. On a bad day, the proprietor demands the designer/engineer to cover the damage along with the engineer to offer a solution at no cost.

Another rationale that a pipe stress analysis is done would be to boost the life span of piping. Most engineers will not believe a piece of pipe to function as gear, but It’s not any different compared to a pump. It is maintained correctly to ensure a suitable life and to protect gear because a pipe isn’t anything more than a significant lever arm attached to some delicate piece of gear. If not properly encouraged and Designed, it could have catastrophic results on this equipment.

There are a few common reasons that could warrant a pipe stress analysis, in addition to those above. They comprise:

♦ Elevated temperatures (>250°F)

♦ Sensitive equipment connections

♦ Enormous D/t ratio (>50)

♦ Piping subject to external pressures.

♦ Critical Services

The Key when doing a pipe stress analysis is determining the necessary level of detail.

Goal Of Piping Stress Analysis:

Structural Integrity:

Design adequacy for the pressure of the carrying fluid.

Failure against various loading in the life cycle . Limiting stresses below code allowable.

Optimal Design:

Avoiding excessive flexibility and also high loads on supporting structures. Aim towards an optimal design for both piping and structure.

Governing Codes and Standards:

Codes and Standards specify minimum requirements for safe design and construction (i. e. provides material, design, fabrication, installation and inspection requirements.)

Pipe Pressure analysis computer versions are a collection of 3-D beam components that produce a depiction of their piping geometry. Three-dimensional beam components are the most effective means to model the piping system, but not always the most precise; and with no complicated finite element models, it’s almost impossible to account for all. But, it’s known from historic empirical testing these approaches and 3-D beam pc versions reveal enough behavior that they are a fantastic approximation. Additionally, piping codes, for example, ASME B31, have security margins that allow for approximation.

The computer models are just as good as the data entered into them. It’s important when creating a pipe stress analysis, just like any finite element analysis (FEA) model, to also know the physics and boundary conditions of the design.

Elements used to model the piping system have their own limits. Thus, ASME has developed stress-intensification factors (SIFs) for piping fittings throughout empirical testing. They allow for increased approximation without using complicated FEA models with bubbles, shells, and brick components. It is vital to be certain these constraints are considered when creating a pipe stress analysis. Most pipe pressure analyses don’t function as a high profile FEA software bundle.

The 3-D beam component behaviors are ruled by bending minutes. As mentioned above, it’s effective for many investigations and adequate for system investigation. But, there are drawbacks to using a 3-D beam component:

♦ No adverse consequences will be viewed on the pipe

♦ No second-order consequences

♦ No huge turning

♦ No accounting for a large shear load

♦ Wall deflection happens before bending failure

♦ Brief, fat cantilever versus extended and skinny

♦ No shell/wall outcomes could be viewed

Working Of Piping Stress Analysis:

- Pipes would be the most delicate element in almost any process plant, they’re also the busiest entities. Piping Systems are exposed to just about all sorts of heaps, intentional or unintentional. It is extremely important to be aware of potential loads a piping system could experience during operation in addition to during other phases in the life span of a process plant. The machine could fail in the first event of the overlooked load. Failure of a piping system can trigger a Domino impact and lead to a significant disaster.

- Since the pipe temperature varies from the setup requirement into the functioning state, it expands or contracts. From the overall term, both instances are known as thermal growth. When a tube expands it’s the potential of producing tremendous force and pressure within the system. But, if the piping is elastic enough, the growth could be consumed without producing undue pressure or stress.

- Piping is used to carry a specific quantity of fluid from one stage to another. It’s clear that the shorter the pipe is utilized the lower the capital expenditure is necessary. Long pipe runs can also create excessive pressure fall making it unsuitable for the right operation. On the other hand, the direct shortest design generally isn’t suitable for consuming thermal growth. Flexibility evaluation is completed on the piping system to examine its behavior when its temperature varies from ambient to functioning, in order to arrive in the most economical design with sufficient security. Piping flexibility is offered in a number of various ways.

- When a pipe is bent inside its elastic limit (no permanent deformation), then it is going to act as a spring and return to its initial shape after the load is removed. When the pliers and elbows to a tube system are organized to permit motion, the forces will be a lot less than a straight run. Additionally, the turns and offsets necessary for running the pipe from one stage to another to provide some versatility too. This inherent flexibility may or might not be sufficient based on individual scenarios.

Why is Piping Stress Analysis important?

Piping stress analysis is important because it helps to ensure the safe and reliable operation of piping systems. These systems are typically subjected to a variety of forces during operation, including thermal expansion and contraction, pressure, and external loads such as wind or earthquake forces. If these forces are not taken into account during the design of a piping system, it can result in structural failure, leaks, or other issues that can be dangerous and costly.

Piping stress analysis is used to identify the stresses that will be imposed on a piping system during operation, and to ensure that the system is capable of withstanding these forces. This is accomplished through the use of specialized software and engineering techniques, which allow engineers to model the behavior of the piping system under various conditions. By analyzing the stresses on a piping system in this way, engineers can identify potential problem areas and take steps to address them before they lead to failures or accidents.

Overall, piping stress analysis is an essential aspect of the design and maintenance of piping systems, and is critical for ensuring the safety and reliability of these systems.